What is a Finger SPLICE?

For Finger Splices, plies are split or separated, fingers are cut and matched, and lap areas fused or thermo-welded together. This result is a tight, strong flexible endless splice belt. Finger splices can be performed on an air-cooled or a water-cooled press. This method is especially suitable for single-layered belts.

STRAIGHT FINGER SPLICE PROCESS

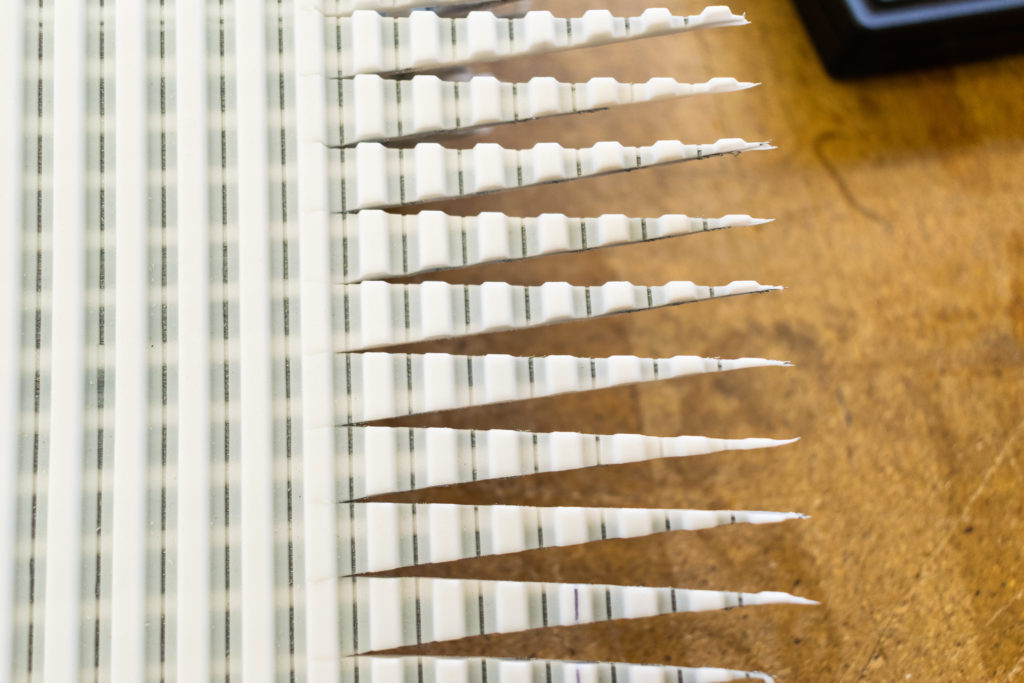

- STEP 1: A zigzag pattern is punched into both sides of the belt, creating several interlocking “fingers.”

- STEP 2: These fingers are carefully and tightly aligned on the press.

- STEP 3: A silicone matrix layer is added on top of the belt

- STEP 4: The pressure, temperature and dwell time are set and the press is closed.

- STEP 5: After the belt is vulcanized release the press and trim off any shims that were used.

BENEFITS OF FINGER SPLICING

- Produces highest tensile strength bond

- Reduces noise

- Great for the food industry.

The welding process seals the belt (cords and fibers) eliminating any places for germs to hide. - Maintains the surface integrity of the belt

- No plastic or metal parts to break off

- Basically disappears on the belts surface.